Airbus has taken another important industrial step towards serial production of the A321XLR long-haul aircraft.

Together with hangars 260 (pilot line) and 259 (equipment assembly), the new line in hangar 246 forms the infrastructure for serial production of the A321XLR at the Airbus site in Hamburg.

What happens in hangar 246?

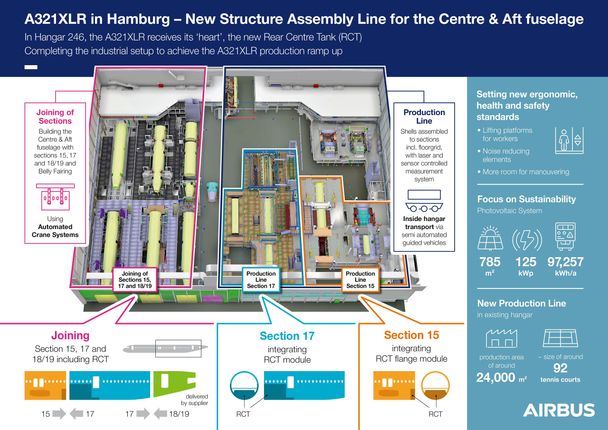

The A321XLR revolutionises long-haul flights. The heart of the aircraft is the rear centre tank, which is part of the structure of the rear fuselage and located in section 15 and 17. These sections are assembled using shells and joined with section 18/19 (delivered by a supplier) to form the rear fuselage of the A321XLR. The new, modern structure assembly line, which was installed in a former A380 hangar over the past months, has a 24,000 square metre production area employing around 300 people.

New standards for ergonomics, health and safety

In addition to utilising state-of-the-art tools as well as laser and sensor controlled measurement systems, ergonomic and energy-efficient aspects also played an important role in the planning of the hangar. Large photovoltaic panels are installed on the outside of the hangar. Noise containment elements were installed as well as lifting platforms at working stations to avoid climbing steep stairs and provide optimised ergonomic access to the sections. The floor grid is assembled vertically instead of horizontally to prevent workers from working in an uncomfortable position such as kneeling. Furthermore, the working stations are designed in a more efficient way resulting in more space to easily move around the working platforms.

André Walter, Head of commercial aircraft production in Germany and CEO of Airbus Aerostructures, was enthusiastic at the inauguration ceremony: “Great company, great colleagues, a great moment.” He emphasised that the start of the new structure assembly was the last brick needed to finalise the industrial setup for the A321XLR in Hamburg, including the many other Airbus plants that have their share in this product.

The A321XLR in Hamburg is ramping up

Production of the A321XLR is already running at full speed in Hamburg. The new structure assembly in hangar 246 will make a fundamental contribution to achieving the production rates.

Gary O’Donnell, Head of the A321XLR programme, said at the occasion of the inauguration. “Our industrial system is one of the most complex and dynamic in the world. The high level of technology, precision and enormous knowledge in interaction with the many suppliers is absolutely unique. What we see here is the result of the incredible knowledge of our people.”

With the inauguration of hangar 246 Airbus reached the final milestone for the industrial set-up for the A321XLR ramp-up in Hamburg - from structural assembly to equipment installation and final assembly. Entry-into-service of the new aircraft is planned at the end of the summer.